January 18, 2024 By Jim Hammerand Leave a Comment

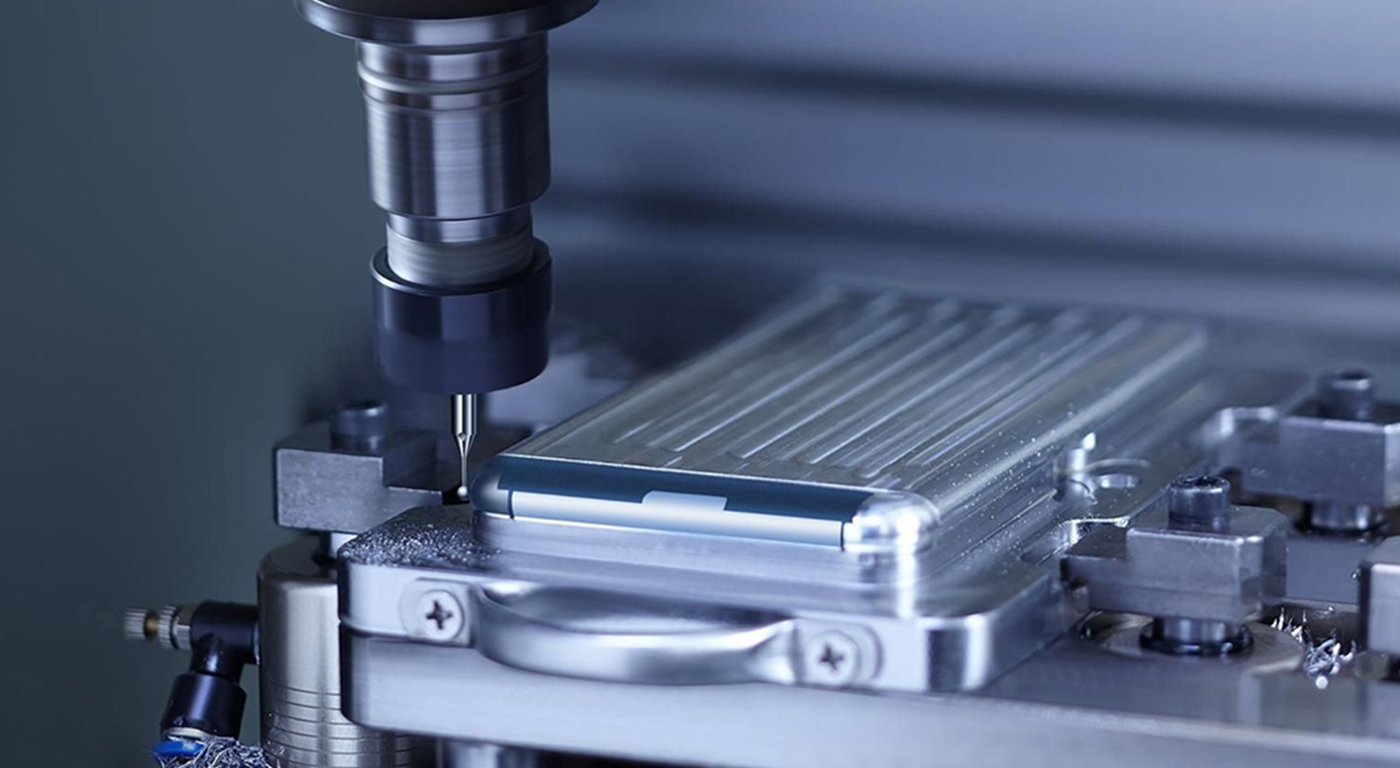

Medtronic uses six nitinol wire struts for each Harmony transcatheter pulmonary valve (TPV).[Photo courtesy of Medtronic] Small Cnc Machining

We’ve previously covered how medical nitinol is mined and melted into raw material and then processed into nitinol wires, tubes and sheets for device manufacturers to use in medical devices, components or parts.

Laser cutting nitinol tubes and sheets is the most common way to manufacture nitinol medical devices, components and parts. Laser cutting is used for common products, including stents, heart valves, inferior vena cava (IVC) filters and most other nitinol implants.

More advanced than fiber lasers, femtosecond lasers can cut medical grade nitinol with ultra precision without heating the alloy, which is sensitive to heat changes.

Other nitinol machining and manufacturing methods include:

After laser cutting — or an alternative machining process — comes deburring (if needed) and then shape setting.

Nitinol shape setting uses a tooling fixture to compress or expand the nitinol into the desired final form, and heat from a salt bath, fluidized bed or furnace to treat the nitinol so it maintains that shape.

The heat applied in shape setting also affects the special shape memory and superelastic/pseudoelastic properties of nitinol. Different heat treatment temperatures and times will yield different properties, giving a stent radial force to resist crushing, for example, or allowing a minimally invasive implant to compress down into a catheter for delivery and then expand when placed inside the patient. The nitinol’s fatigue durability is another property that is affected by heat.

Shape setting is also a stage where nitinol can be given different colors and shades (like you might get by anodizing titanium) with different applications of time, temperature and atmosphere in the furnace. A traditional anodization process can also be used to give nitinol a colored finish, similar to what you might do with aluminum.

After shape setting, surface finishing for oxide removal is a necessary step for biocompatibility. This step prevents the harmful effects of long-term nickel exposure to the human body. There are benefits and drawbacks to different surface finishing treatments for nitinol.

Electropolishing and mechanical polishing can ensure biocompatibility and also remove blemishes that could become fatigue nucleation sites.

Electropolishing is a great way to achieve biocompatibility by removing surface oxide while softening sharp edges and creating smooth surfaces. Electropolishing doesn’t have the fatigue drawbacks of pickling or chemical polishing.

Pickling (or etching) uses acid to clean the surface, removing the oxide. Pickling can be used in a batch process by dipping parts into an acid bath to remove oxide for biocompatibility. However, pickling will leave microscopic changes to the surface topography that could introduce the risk of fatigue cracking. But that same surface topography could also enhance adhesion of polymer coatings on devices such as guide wires.

Chemical polishing is a similar acid bath batch process. It leaves a smoother surface than pickling for better fatigue resistance, but still offers some topography for coating applications.

Finally, visual and dimensional inspections verify the quality of the finished nitinol parts, components or devices before assembly and/or packaging, sterilization and shipping.

Alcohol and nitinol needles could make renal denervation for hypertension faster and simpler

You must be logged in to post a comment.

Subscribe to Medical Design & Outsourcing. Bookmark, share and interact with the leading medical design engineering magazine today.

DeviceTalks is a conversation among medical technology leaders. It's events, podcasts, webinars and one-on-one exchanges of ideas & insights.

The Medical Device Business Journal. MassDevice is the leading medical device news business journal telling the stories of the devices that save lives.

Precision Machining Copyright © 2024 WTWH Media, LLC. All Rights Reserved. The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media LLC. Site Map | Privacy Policy | RSS