Please ensure that JavaScript is enabled in your browser to view this page.

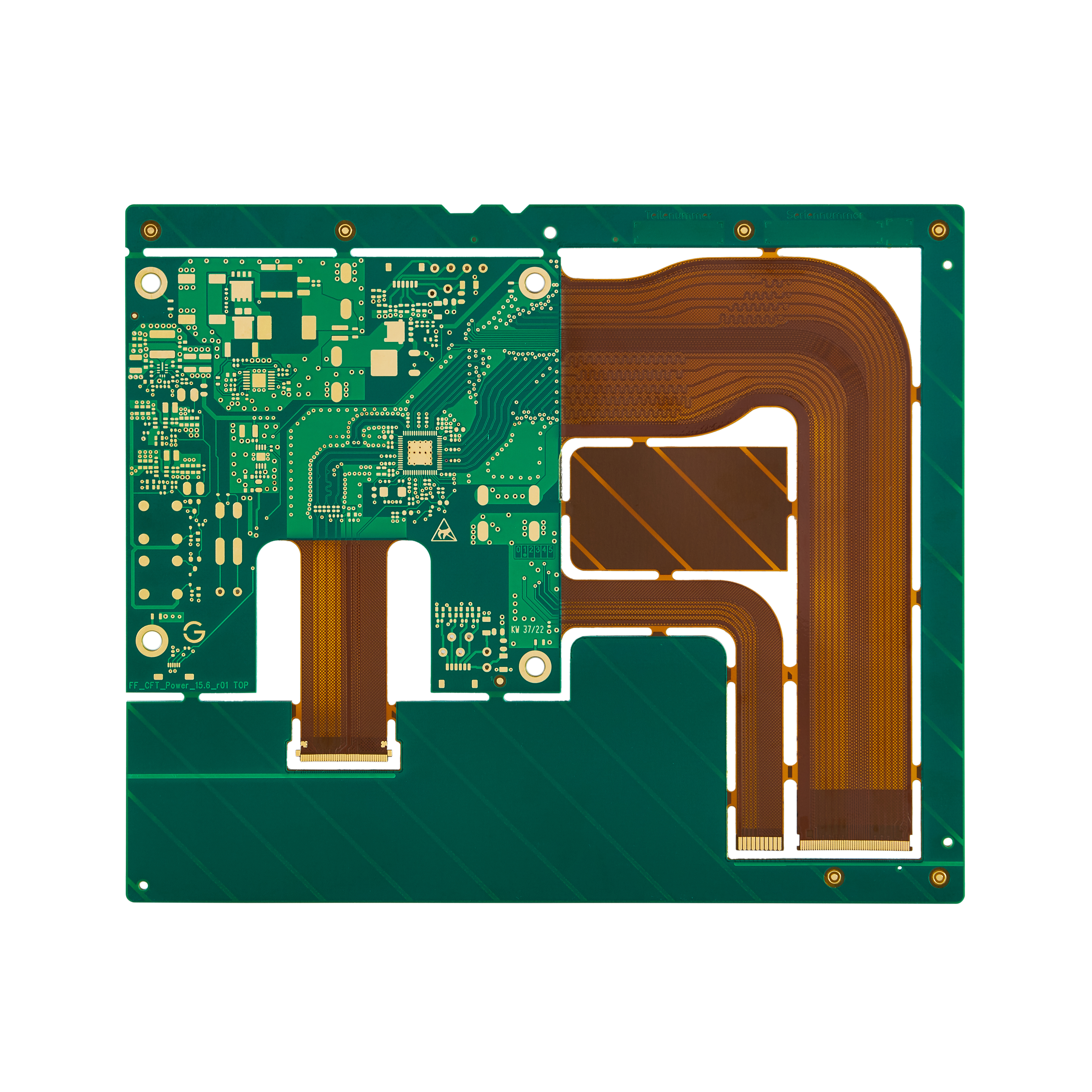

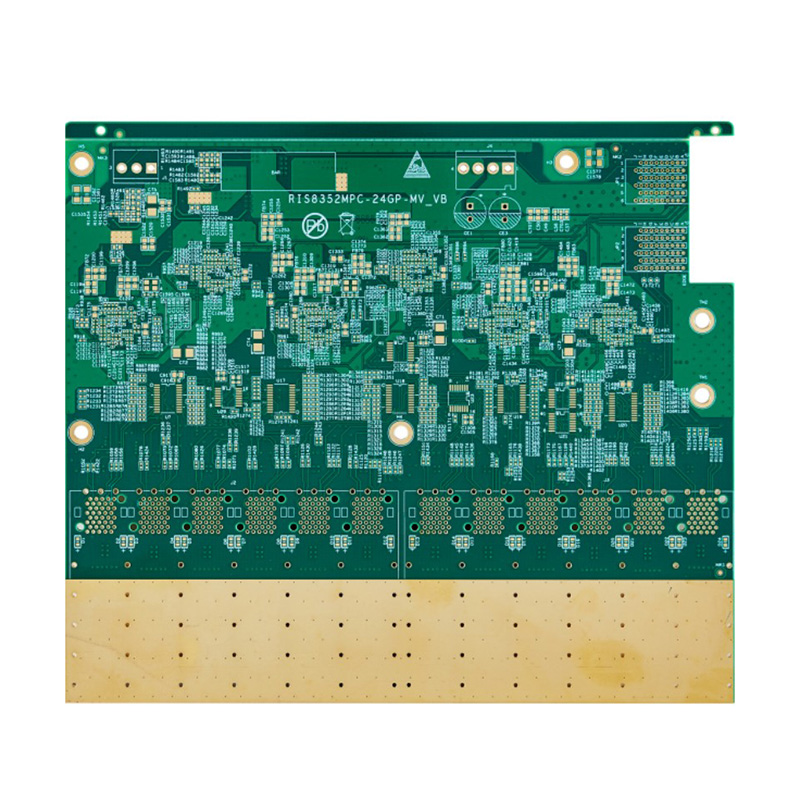

"BadUSBs," or USB devices that can perform malicious actions, have blown up in popularity over the last few years. While some models are only meant to fry the motherboard of the computer they are plugged into, others are far more complex. Automated keypresses, scripting, malware delivery, snooping, and even remote operation are all potential features that could be included in such a device. Board Printed Circuit

Element14 Presents host Clem Mayer has been at work designing his own BadUSB named the "sudostick," owing to how it grants the USB stick's owner almost super-user powers over the target. With the eventual goal to host it on a crowdfunding website, Mayer has gone through several revisions and design decisions in hopes of getting one ready for mass-production, and his latest video details the entire process.

Commercial prototypes can often undergo a couple hundred revisions before they are ready for release, and while the sudostick is not at that level of change, Mayer did need to iterate on his design to take it from a large development kit-sized board to something that could fit inside a standard USB stick format. In addition to the size concerns, he also had to consider how his component and placement selections impacted the cost of getting it assembled and put into a case.

As Mayer points out in his video, opting for automated PCB assembly can drastically reduce the time needed to manufacture a completed board. But beyond the obvious, it also allows the designer to select much smaller components since solder paste and a pick-and-place robot can be more accurate compared to soldering by-hand. Another major consideration is where components go, as the costs of one-sided assembly compared to two-sided assembly are nearly doubled, even if the other side has a single part.

Delivering adequate power in such a small footprint can be challenging. In Mayer's design, there are two low-dropout (LDO) regulators with one of those circuits being placed on the second side. However, this increases both component and assembly cost which prompted him to look for an alternative power management IC (PMIC). By combining different chips into a single one, the number of components and sometimes the cost can be brought down while also freeing up space for other parts on the PCB. Lastly, the USB management circuit was swapped for something more effective and the connector was replaced by one that could undergo assembly without the need for human intervention.

After figuring out what components should be used and designing a new PCB with a plethora of test pads and connectors for debugging, Mayer emphasized the need for piecemeal testing to ensure everything is working as intended. Once that step is complete, another, more condensed PCB can be manufactured to catch layout/packaging mistakes and determine how the user will interact with the device.

Led Lighting PCB Hackster.io, an Avnet Community © 2023