The application of Aerial Spacer Cable Systems (ASCS) in heavily treed areas is very common amongst electric utilities. There are a number of other applications including multiple-circuits, long-spans, under built circuits, over-built circuits, wildlife protection and substation exits that not only provide users with greater reliability but also can potentially save initial project (first) cost as well. One such application is utilizing ASCS for its voltage-drop benefits. In fact, there are a few cases where spacer cable has been used and has allowed a utility to keep from having to build additional transmission lines and a new substation.

Aerial Spacer Cable is a messenger – supported, 3-layer cable system in a close, triangular configuration. The phase conductors are covered using a single layer of semi-conductive polyethylene, a layer of low-density polyethylene and finally an outer layer of track-resistance, high-density polyethylene; they are not shielded or grounded. This covering allows us to place the phase conductors in very close proximity. A typical 15kV system has a phase-to-phase spacing of 8-inches, while 25 to 46kV systems have a phase-to-phase spacing of only 11.5-inches. Single Mode Optical Fiber

By placing the phase conductors so closely and in a triangular configuration, which allows equal spacing between all 3-phases, we can minimize the mutual inductance between phases and effectively minimize the line impedance and therefore, the voltage drop without increasing the size of the conductor.

Our society has become more and more dependent on the electrical system and the demand on that system has increased significantly. Reliable electric service is now considered a necessity and no longer a luxury. System outages are typically not tolerated by users. In many cases, momentary outages (blinks) can bring in even more complaints. Voltage support is very important to all electric utility end users but, especially their commercial and industrial customers. Adequate and sustained voltage at the delivery point is critical to most computer systems and electrical motor (starting) loads. Most utilities are required to supply system voltage at the metering point to a tolerance of 5%. However, in many cases, lower tolerances are required.

For the most part, C&I loads are in an area close to the distribution or transmission substation and voltage at the delivery point isn’t a concern, current loading is the focus. However, with commercial real estate pricing increasing and availability decreasing, some of these larger system loads may be further from the substations. Or, in some cases, the substations themselves are located further from the loads than the utility would prefer. Additionally, as more and more utilities are installing renewable sources of generated power and these facilities tend to be a great distance away, even remote in some instances.

Distribution and transmission utilities typically address voltage drop concerns in a couple of ways. The utility can increase the size (diameter) of the conductor or by installing line devices such as step-voltage regulators. These can be costly options.

The utility is somewhat limited in the sizing of the conductors due to mechanical loading on poles due to snow, ice and wind loading. In many cases, they are also required to delivery multiple circuits which can also increase the number of poles as well as size of the poles (height and class). The greater the number of poles, the increased risk for outage and the increase material cost for the project.

Voltage regulators are also a common option, especially with existing circuits where additional commercial or industrial load is being added. However, distribution voltage regulators are relatively slow, with a delay of over 15-seconds. This can cause significant issues for computer or logic-controlled systems as well as electric motors. Drops in system voltage and slow reactions can, in some cases, activate automatic throw-over switches on backup generator systems creating issues for the end users and, potentially, issues for the utility company.

By either utilizing Aerial Spacer Cable for new construction, or simply replacing existing, open/bare wire conductor with spacer cable, many of these issues can be eliminated. The utility will end up using smaller conductor, few poles; take up less right-of-way space and potentially save money on the initial project cost as well as operation & maintenance cost going forward.

One Mid-West utility had a new C&I customer, a retail space, moving into a part of their service area with limited electric facilities. After evaluation, they determined that installing approximately 9-miles of 795 kcmil Hendrix Aerial Spacer Cable would be a more cost effective solution than the additional transmission line and substation required to adequately serving this customer.

Hendrix Aerial Spacer Cable was also used for project at the D.B. Wilson Power Plant in Centertown, KY. The scope for that project included a new distribution circuit serving 3, 500 HP pumps, 3 MVA of barge loading equipment and 500kVA of miscellaneous electrical equipment over a distance of 1.69 miles. The case study determined that Aerial Spacer Cable was the most economical method to serve this load.

Hendrix Aerial Cable Systems has been improving the reliability of distribution electrical systems since 1951. Aerial Spacer Cable can provide not only provide greater reliability, but lower O&M costs over the lifetime of the circuit, and in some cases, lower initial project material and labor costs. If you have a project where voltage drop is a concern either due to location or length from substation facilities, motor starting load or overall electrical capacity, Aerial Spacer Cable may be the best solution. Please contact your local Hendrix Aerial Spacer Cable Sales Representative.

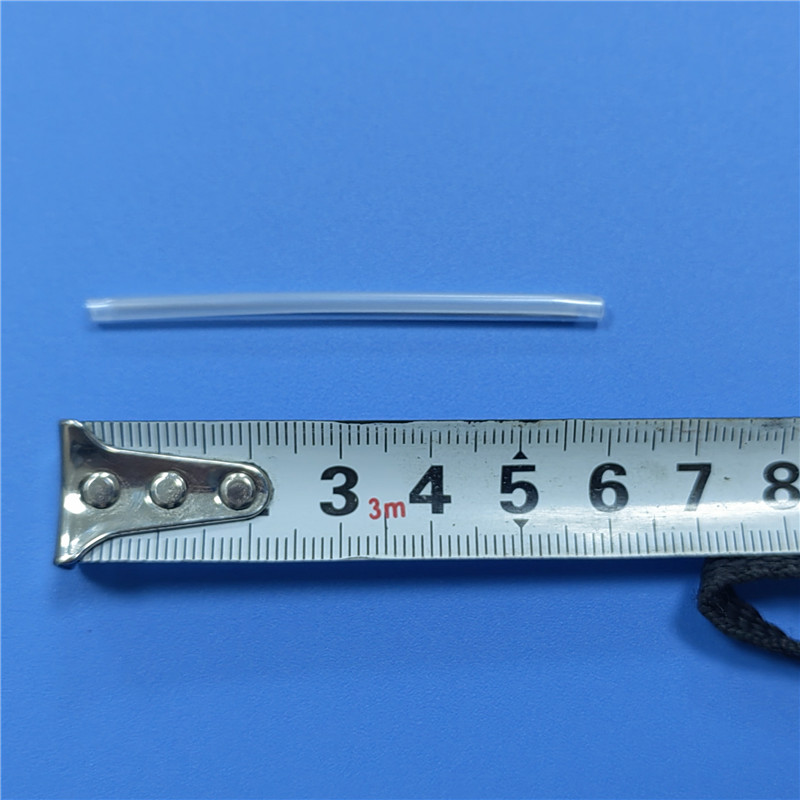

Fiber Optic Cable Protection Sleeve We provide a full line of engineering and construction services. Focusing on each and every customer’s individual needs, we have the resources to provide anything from a simple spacer cable design review to full engineering support. We also are able to assist in construction coordination and management. We can assist with initial site walk-down, installation and maintenance training and on-site construction support. We prefer to be a partner through all phases of a project – before, during and after – versus simply a manufacturer.