Welcome to the official blog of the International Society of Automation (ISA).

This blog covers numerous topics on industrial automation such as operations & management, continuous & batch processing, connectivity, manufacturing & machine control, and Industry 4.0. Milling Small Parts

The material and information contained on this website is for general information purposes only. ISA blog posts may be authored by ISA staff and guest authors from the automation community. Views and opinions expressed by a guest author are solely their own, and do not necessarily represent those of ISA. Posts made by guest authors have been subject to peer review.

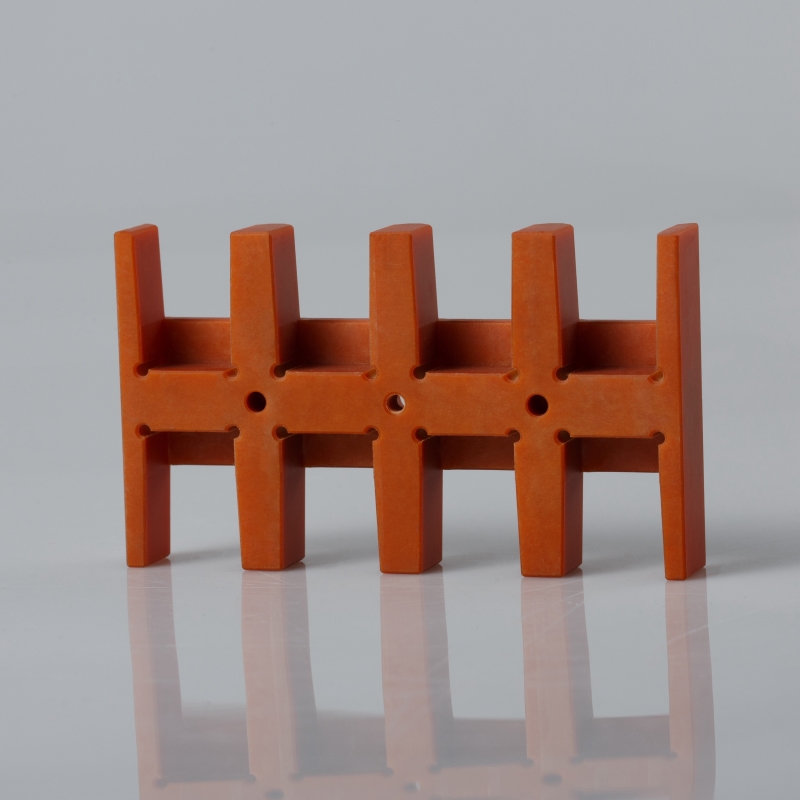

Vacuum casting factories are at the forefront of producing high-quality plastic parts for a range of industries including automotive, aerospace, medical, and consumer goods. These factories use the vacuum casting process to produce parts that meet specific requirements in terms of size, shape, and functionality.

The vacuum casting process involves three main steps: CNC machining of the master model, making a silicone mold, and reproducing the parts by vacuum casting. Following, we'll dive deeper into each of these steps and explore how they contribute to producing high-quality plastic parts.

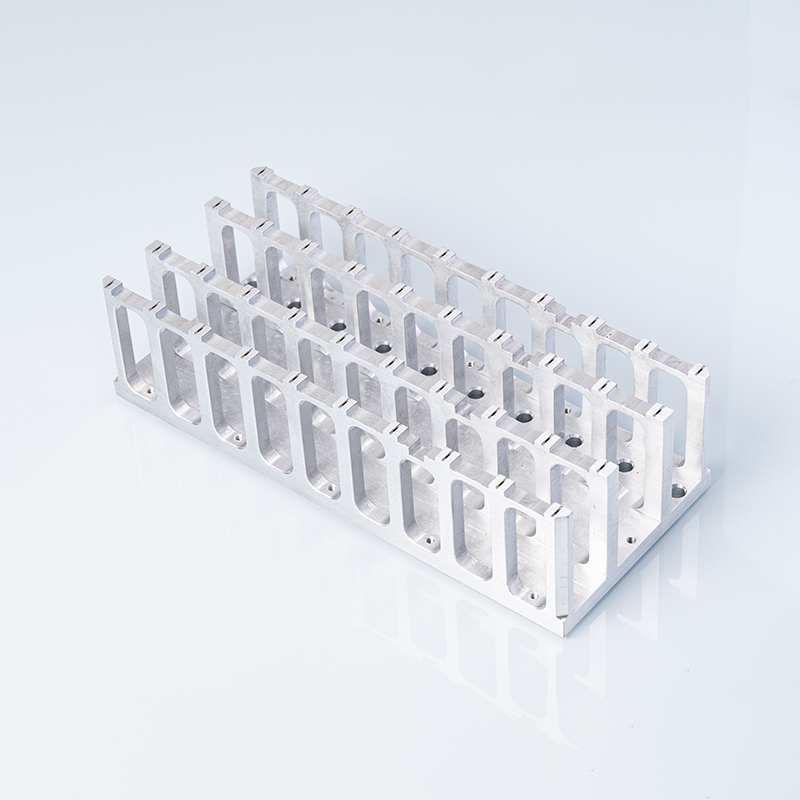

The first step in the vacuum casting process is to create a master model of the desired part using CNC (Computer Numerical Control) machining. CNC machines use computer programs to control the movement of cutting tools, resulting in highly accurate and precise shapes.

The master model is usually made from a solid block of material like wax, plastic, or metal, dependent on the desired end product and the available technology. Once the CNC machine has finished creating the master model, it's ready to be used to make the silicone mold.

The next step in the vacuum casting process is to create a silicone mold from the master model. Silicone rubber is an ideal material for making molds because of its flexibility and ability to capture even the finest details.

To make the mold, the master model is placed in a container and surrounded by liquid silicone. The silicone is then left to cure and harden, creating a flexible mold that can be removed from the master model.

Once the silicone mold is complete, it's time to start reproducing the parts using vacuum casting. The silicone mold is placed in a vacuum casting machine while liquid plastic is poured into the mold. The vacuum casting machine then uses vacuum pressure to draw the plastic into the mold, ensuring that it fills every detail.

The mold is then left to cure and harden, creating a high-quality plastic part that's an exact replica of the master model. The part can then be removed from the mold and the process can be repeated to create multiple parts.

Receiving high-quality parts from vacuum casting factories requires working with an experienced and reliable manufacturer. When choosing a vacuum casting factory, it's essential to consider several factors that can impact the quality of the parts produced.

One of the most important factors to consider is the expertise and experience of the factory. A vacuum casting factory with years of experience and a proven track record of producing high-quality parts is more likely to deliver the desired results.

Another factor to consider is the technology and equipment used by the factory. Modern and well-maintained equipment can produce more accurate and precise parts, leading to higher quality and consistency.

The materials used by the vacuum casting factory are also critical. Using high-quality materials can ensure that the parts produced are durable, reliable, and meet the desired specifications.

Lastly, communication is key when working with a vacuum casting factory. Clear communication between the manufacturer and the customer can help ensure that the parts produced meet the desired requirements and that any issues are addressed promptly.

To receive high-quality parts from vacuum casting factories, it's essential to work with experienced and reliable manufacturers who use modern technology and high-quality materials. Clear communication between the manufacturer and the customer is also critical to ensuring that the desired results are achieved.

Additionally, when working with a vacuum casting factory, it's crucial to understand the limitations and capabilities of the process. While vacuum casting can produce highly accurate and detailed parts, it may not be suitable for parts that require extreme precision or have complex geometries.

It's also important to consider the quantity of parts needed. Vacuum casting is a cost-effective method for producing small to medium quantities of parts. For larger quantities, injection molding may be a more suitable option.

The material selection is an essential aspect to consider when producing parts using vacuum casting. The vacuum casting process is compatible with a wide range of materials like polyurethane, silicone, and epoxy resin. The material used will depend on the desired properties of the part— including strength, flexibility, and temperature resistance.

In addition to material selection, the post-processing and finishing of the parts are also crucial. The parts may require additional processing, such as trimming, polishing, or painting, to achieve the desired appearance and functionality.

Precision Cnc Turning In summary, vacuum casting factories are an essential part of the manufacturing process for producing high-quality plastic parts. Understanding the process and working with experienced and reliable manufacturers can help ensure that the desired results are achieved. By considering factors like technology, material selection, and post-processing, the parts produced using vacuum casting can meet specific requirements in terms of size, shape, and functionality.