Virginia Man Uses Brute Force Splitter; Keystone Machines Key Mill That Makes Stakes

Charles Reed operating his Blockbuster model 14-12 firewood processor. He and his son modified the machine to be able to process logs up to 16 inches in diameter and 20 feet long. Wood Shredder Machine

AYLETT, Virginia – Charles Reed grew up in the forest products industry, and now his son, Will, is working with him in it. Together they operate two businesses – one that makes wooden stakes, and the other, a firewood business.

Their firewood business, CWR Firewood & Mulch, continues to grow, and Charles has plans to grow it further by adding kiln-drying and firewood packaging operations in the future.

The Reeds live in Aylett, Virginia, a small community in King William County, a little over 25 miles from downtown Richmond.

Charles, 54, also known by his nickname, ‘Buck,’ grew up in King William. In fact, his ancestral home is located on the 60-acre farm that now contains his stake mill and firewood operations, which together comprise about 10 acres.

His father, William Reed, operated a sawmill, B.D. Reed Lumber, less than a mile away. He cut hardwood into railroad ties and pallet stock and also produced firewood and mulch. His father died in 1991.

Charles worked for his father as a teenager – operating loaders, sawing, running the edger. His father helped him get set up making wooden stakes in 1982. Charles was about 14 at the time. “I went to school during the day and cut stakes ’til late at night.”

Charles and his son, Will, who operates the firewood business with him and also works in the stake mill. They bag some firewood so customers can pick it up from a shed on the property and leave their payment in a cash box.

In the early 1990s Charles bought a wood furnace to heat his nearby home and began producing his own firewood, cutting logs by hand with a chainsaw and splitting the rounds with a horizontal splitter. He gradually began producing and selling firewood for other people when they asked him for firewood.

Charles officially added firewood to his business as a separate business entity in 2010. “Another hobby,” as he put it. That was the year he bought a Blockbuster firewood processor. (Blockbuster has ceased manufacturing new firewood processors but continues to supply parts for its equipment.)

Will, 20, works with his father in both enterprises. He represents the third generation of “sawdust bleeders,” said Charles. They normally run the stake mill Monday through Thursday and produce and firewood on Friday.

Firewood sales in recent years have run around 1,000 cords although this year sales probably will only reach about 550-600.

King William is a rural county, as are its neighboring counties, for the most part, and the abundant forest resources supply a number of different sawmills and a paper mill.

“I deal with all local people,” said Charles. All the logging six or seven contractors who supply him with logs are “family friends.”

He buys low-grade hardwood logs, mainly white oak, red oak, and hickory, and some other species. The logs may come off timber sales or a lot being cleared for a house or some other development project. Logs range from 5-16 inches in diameter and 14-16 feet long.

An ancient (1981) John Deere 690 excavator – dubbed ‘Brutus – with a grapple attachment is used for unloading log trucks. The Reeds have a Kubota SSV75 skid steer for loading logs on the processor’s live deck and performing other tasks. They also have a Brute Force Stumpbuster 30-30, an attachment for the skid steer that is used to split rounds of oversized logs.

Charles and Will use this Kubota skid steer with a Brute Force Stumpbuster 30-30 attachment for splitting rounds from oversize logs.

Brute Force, based in Wisconsin, offers a complete line of firewood processing machines. The company also manufactures splitters and equipment for cleaning, conveying, and bundling firewood. For more information about the company and its products, visit www.bruteforceusa.com.

Charles was somewhat familiar with other manufacturers of firewood processors, researching them on the Internet. He also had viewed machines at the East Coast Sawmill and Logging Equipment Exposition, also known as the Richmond Expo and held biennially in nearby Richmond. He was sold on the capacity of the small machine and Blockbuster’s commitment to parts availability. “They have the best parts service of any company I have ever dealt with,” he declared. He has bought any parts he needed from Blockbuster, including saw bars, chains, and hydraulic pumps.

The Blockbuster model 14-12 firewood processor is on its second Briggs & Stratton Quantum gasoline engine, which generates 32 hp. The engine is closing in on 5,000 hours of service. The processor utilizes an 18-inch bar saw for bucking.

Charles and Will have modified the processor over the years, mainly to accommodate logs that are longer and larger diameter. The machine now can process logs up to 20 feet long and 16 inches in diameter.

The machine has performed well. “It well exceeded my expectations,” said Charles, who does regular preventive maintenance.

“It’s one of the toughest machines I’ve ever owned, and the most reliable,” he added.

The processor is set up under a metal pole shed to protect it from the elements. The finished firewood can be routed into one of two conveyors and top-loaded into trucks. Will fabricated both conveyors. “We like to tinker,” said Charles.

Finished firewood is seasoned under roof in an open air shed adjacent to the stake mill. It results in wood that is much drier, according to Charles, compared to firewood that is left outdoors to season, exposed to the rain and elements. The firewood is stacked inside metal or wooden baskets that can be stacked atop each other in the shed.

The Reeds salvaged metal racks and added boards on the sides to create baskets for storing their firewood. The finished firewood is stored under roof in this shed to keep it dry and improve seasoning.

The company delivers firewood up to a distance of nearly 100 miles. Beside King William, they have customers on Virginia’s Middle Peninsula and Northern Neck. The business is equipped with three trucks for making deliveries.

Charles charges the same price for firewood delivered across the street and an order hauled 90 miles away; there is no additional delivery fee. The company normally does not provide stacking services unless the customer is elderly.

He doesn’t advertise the firewood business, other than a Facebook page Will created in 2014. “We have the same customers,” explained Charles.

Some of his customers are restaurants that burn wood for pizza ovens, for example. Hickory is separated and supplied to barbecue restaurants. In fact, he has supplied hickory wood to restaurants as far away as Florida.

Charles also sells small mesh bags of firewood that are stored in a tiny shed close to the highway his property fronts. There is a small locked cash box for customers to insert their money or a check under an ‘honor system’ if Charles and Will are not onsite or readily available.

Charles also buys a couple of types of mulch as well as gravel and decorative stone and resells the materials. They can use the Kubota skid steer to spread the gravel and stone.

The stake mill operates under Rice’s Stake and Wood Products Inc. Charles has a partner in the business, his brother-in-law, G.C. Rice, who also drives a truck for the company. The stake business has generated more than $1 million in sales in some years and employed as many as 15 people, although sales have dropped to about $300,000 in recent years. “When dirt movers and surveyors are down, we’re down,” observed Charles. In the current economic climate, the stake mill usually runs with a crew of five.

For making stakes, Charles buys 6/4 hardwood from small sawmills in the region and 4/4 kiln-dried No. 2 and better pine from East Coast Lumber near Greensboro, North Carolina. He buys lumber in 6-8-inch widths and 2-foot increments from 8-14 feet.

The material is cut to 4, 5- or 6-foot length on a Keystone five-head multi-trim saw and feeds directly into a Pendu gangsaw to be ripped to the proper width, such as 2×2 and 1-1/2×2. The strips are collected on a conveyor that carries them behind two Keystone stake pointers; a worker at each machine can remove strips from the conveyor and feed them into the stake pointer. Finished stakes are stacked by hand. The stake mill is equipped with a Weima grinder to process trim ends and other scrap.

Stakes are supplied to surveyors and construction companies in the greater Richmond region as well as Hampton Roads, Northern Virginia, North Carolina and Maryland.

Pennsylvania-based Keystone Machinery specializes in manufacturing stake pointers and sawmill equipment. The company’s product line includes sizers, gang saws, rip saws, edgers, end trim saws, cut-off saws, and various material handling equipment, such as pit unscramblers, stackers, run-arounds, accumulators, and tilt hoists. For more information, visit www.keystonemachine.org.

Charles also has a Wood-Mizer LT40 hydraulic portable sawmill that he bought as a hobby – for “stress relief.” He and his son have another mutual hobby. “Will and myself are into trucks. Hot rod pickups.”

Charles and Will have begun work on building a kiln to dry their firewood. They have a steel container box in place. He plans to use a wood-fired boiler to produce hot water that will go into a system of coils, and three fans that will blow the air heated by coils. The fans will be supplied by Nyle Systems, which has been providing Charles with some free consultations.

He also is considering adding equipment and operations to package firewood.

Charles also has begun a project to recycle residual material into compost. It is a mix of sawdust, wood grindings – he contracts with a logger to process some logs with a mulching attachment – and top soil, and leaves. “We’re recycling our waste material.”

The row of material is turned periodically with the skid steer. It is a four-year process, according to Charles. He also has been giving away some wood fiber material for horse bedding.

The businesses took a back seat when Charles’s wife, Patricia, was diagnosed with a type of leukemia in 2017. (She has been cancer-free for several years.) Her illness produced an outpouring of support from the community – which the Reeds have reciprocated.

“Customers called every day,” Charles said, inquiring about Patricia, and also sent cards to the family. “Our customers are pretty much our family,” he added.

The Reeds also benefited from the support of their local fire department, the Mongohick Volunteer Fire Department. “When she was in the hospital, they catered to our family,” said Charles. In response, Charles and Will both began volunteering with the fire department.

Will also began organizing an annual car show, the Reeds Strong Car Show. Held at the fire station, the first show drew 1,500 people, and 350 cars were entered. It was a fundraiser to help raise money for Patricia’s medical expenses. In successive years, however, it has benefited other families with a cancer patient as well as the Virginia Commonwealth University Massey Cancer Center in Richmond.

Through their connections with other cancer patients, the Reeds have a mailing list of over 60 people they mail cards to every month – throughout central Virginia, other regions, and even other states. They also organize a party every year for a child battling cancer.

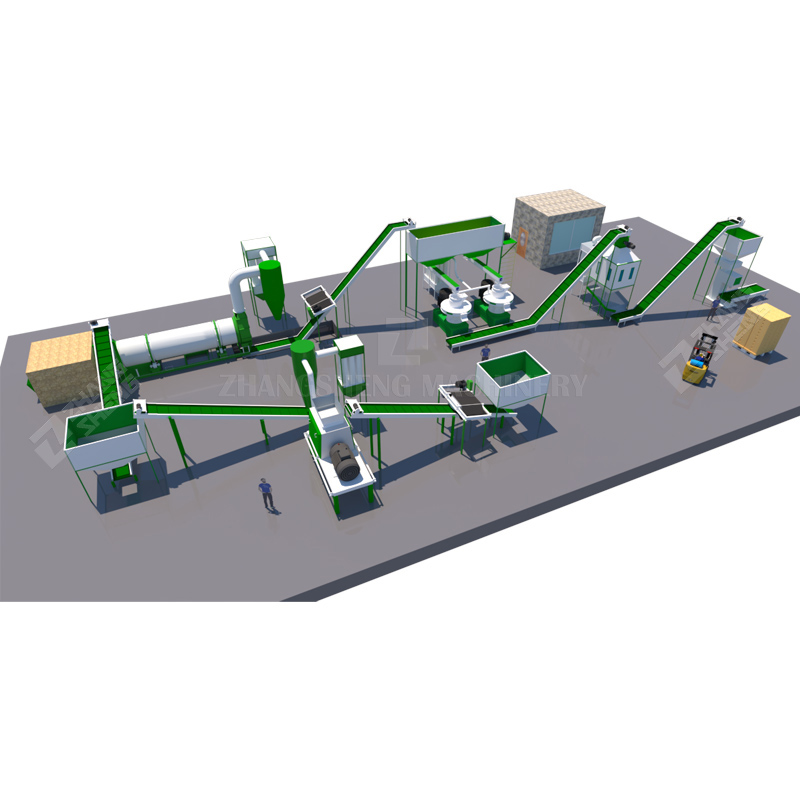

Biomass Pellet Machine Charles is not active in any trade associations, but he participates in the Virginia Department of Forestry Firewood Scout program, which has a website to allow people to search for firewood vendors, and also the state Department of Agriculture and Consumer Services ‘Virginia Grown’ marketing program.